BASF-YPC GAS TURBINE RETROFIT PROJECT————STOP WATER LEAKING INTO THE BASE OF THE GAS TURBINE

CABLE SEALING SYSTEM HSI 150

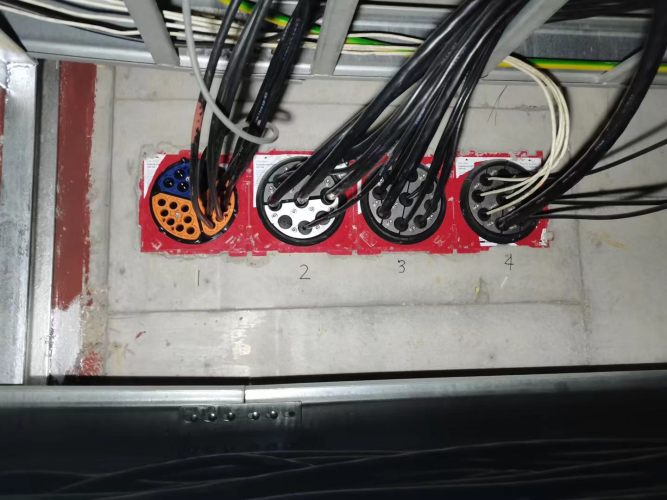

Before the renovation, there was severe water leakage at the base of the gas turbine.

Use foam to seal the cables resulted in severe water leakage.

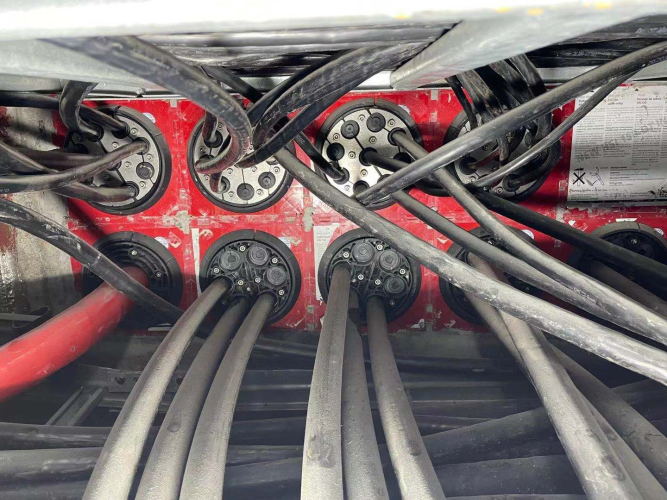

Use wall sleeve together with cable sealing HSI150 DG and HRD to seal power cables and signal cables

Use wall sleeve together with cable sealing HSI150 DG and HRD to seal power cables and signal cables

Use wall sleeve together with cable sealing HSI150 DG, HRD and Segmento to seal power cables and signal cables

Use wall sleeve together with cable sealing HSI150 DG, HRD and Segmento to seal power cables and signal cables

Project information and solution provided by AMPdossen

PROJECT INFORMATION

| Project time | 2020.12 |

| Location | No. 222, Yixi Road, Liuhe District, Nanjing |

| Owner | BASF-YPC Company Limited |

| Installation company | Sinopec Nanjing Engineering &Construction Incorporation |

SOLUTIONS BY AMPdossen

| Specification | Wall insert, cable seal and connection |

| The solution | At the bottom foundation of the gas turbine, the wall sleeve HSI 150-K2-Varia/200-260 is embedded. Then, the wall sleeve is connected with conduit external connector HSI 150-M110 and 168. Finally, the cable sealing is used to seal the power cables and signal cables. |

| Products used | HSI 150-K2-Varia/200-260 HSI 150-M110 HSI 150-M168 HSI 150-DG-1/36-70 HSI 150-DG-3/24-54 HSI 150-DG-6/10-36 HRD 150-SG-6/8-35 HRD 150-SG-9/6-25 HSI 150-S3 SEG 8/15 SEG 6/21 SEG3/26 SEG 2/31 HSI 150-D3/58 |